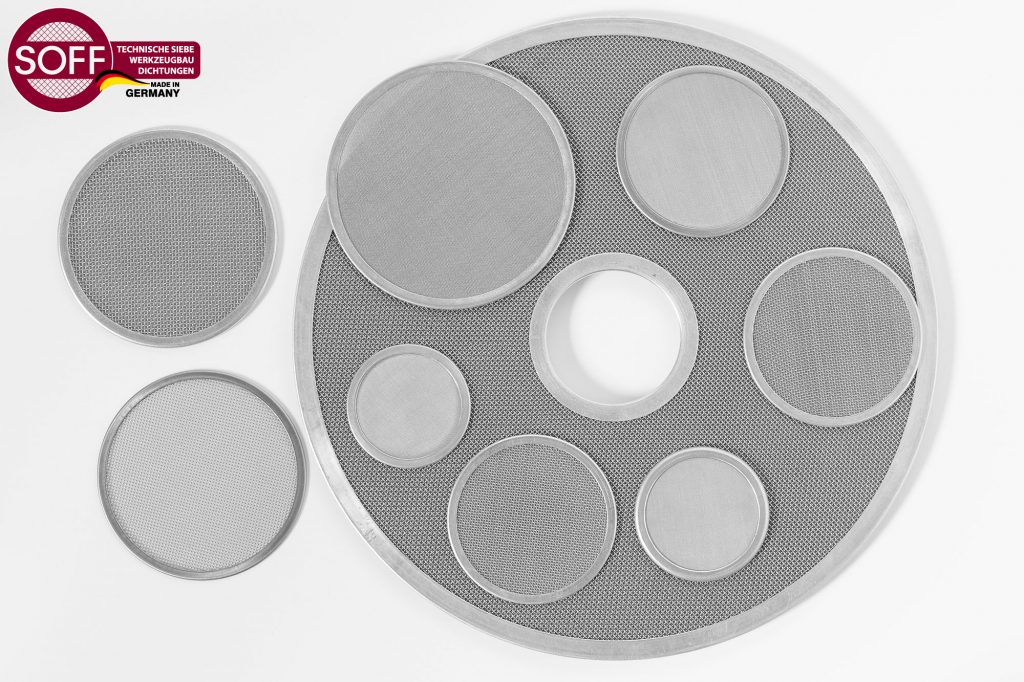

Encased screen discs

Framed Sieve Rounds / Filter Rounds

Our product range includes framed sieve rounds from 12.2 mm in diameter up to 175.6 mm in diameter. Framed sieve rounds can be manufactured with either a single filter layer or multiple layers and/or support layers.

Currently, we produce framed sieve rounds with up to 12 filter inserts. Manufacturing is done according to customer specifications. Our filter rounds are generally made from metal wire meshes 1.4301 / 1.4401, metal fiber tiles, twill weave, or polyester, among others.

In the specified diameter range, we have almost all common dimensions. As a customer, you benefit from not having to invest in initial costs/tooling costs, allowing even small quantities for special machines, test series, or research projects to be realized quickly.

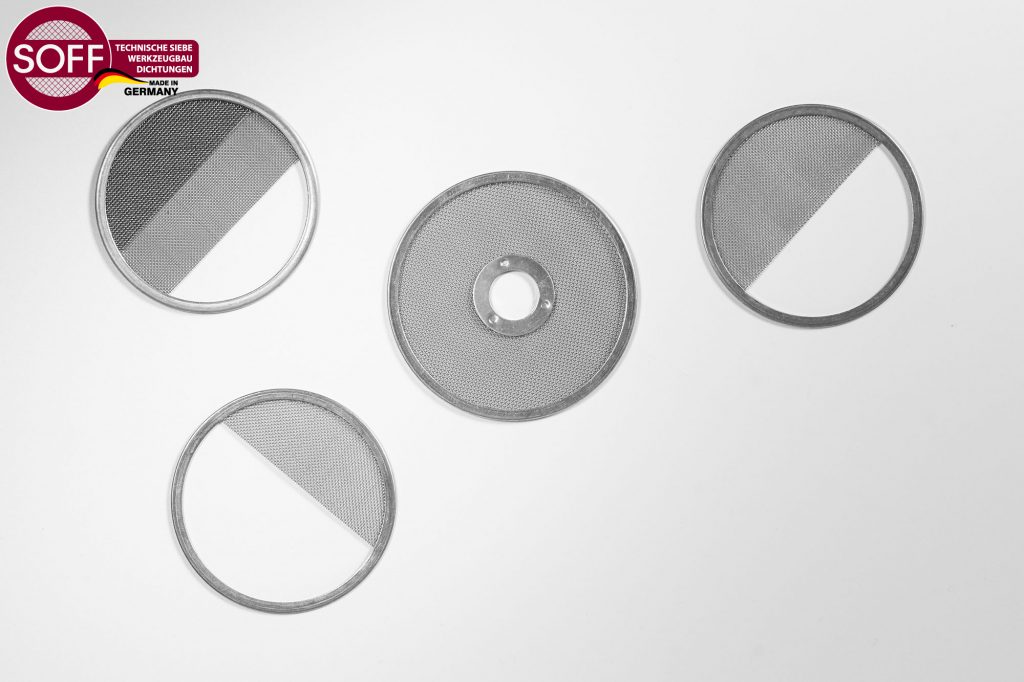

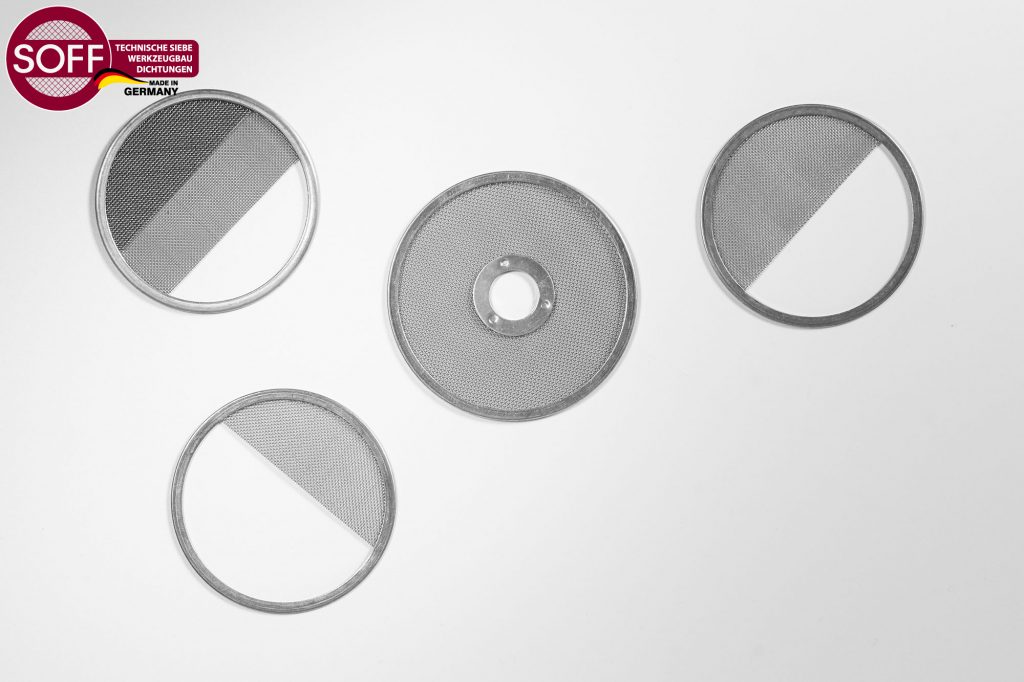

Markings of the inflow side, as well as other identifications of the mesh type, can be applied to the framing of the sieve rounds.

If there is no suitable tool set or diameter in the desired dimensions, we can quickly and affordably manufacture it in our tool shop.

Framing

The framed sieve rounds can be made from aluminum, stainless steel V2A/V4A, or copper. The thickness of the framing varies from 0.3 mm to 1 mm, depending on the tool set. The framing also serves as a seal. Depending on the requirements, different hardness materials are used to achieve the desired result for the customer. Materials that are too hard prevent the material of the frame from “flowing,” resulting in the seal between the frame and the filter housing not being achieved.

Quality

For the production of the outer frame of our framed sieve rounds, we use only materials with factory certificates. We also focus on quality for the inserts, such as wire meshes. This product quality benefits you in your production process, as only flawless wire mesh delivers optimal filtration results and corresponding service life in filtration applications.

Applications for framed sieve rounds:

- Chemical industry

- Extruder screens

- Rubber manufacturing

- Petrochemicals

- Pump pre-filters

- Plastics processing

- Food and water filtration

- Pharmaceutical industry

- Automotive industry

- Aerospace

- Electronics industry

- Textile industry

- Medical technology

Series Production

In addition to the production of small series and special designs, we also offer the possibility of series production. With our modern production facilities and efficient manufacturing processes, we are able to produce large quantities in consistently high quality. This enables us to deliver on time even with high demands on precision and reliability. Our series production is particularly suitable for applications where a continuous supply of high-quality filter rounds is required.